Embark on the journey of creating a robust Preventive Maintenance Plan for Fleet Trucks with this comprehensive guide that delves into the essentials of maintenance planning.

Exploring the intricacies of preventive maintenance and its impact on fleet trucks, this guide aims to equip you with the knowledge needed to optimize your maintenance strategy.

Importance of Preventive Maintenance Plan for Fleet Trucks

A preventive maintenance plan is essential for fleet trucks to ensure optimal performance, longevity, and safety on the road. By implementing a proactive approach to maintenance, fleet managers can avoid unexpected breakdowns and costly repairs, ultimately increasing the efficiency and reliability of their vehicles.

Benefits of Implementing a Preventive Maintenance Plan

- Increased Vehicle Reliability: Regular maintenance helps identify and address potential issues before they escalate, reducing the risk of breakdowns during operations.

- Enhanced Safety: Well-maintained fleet trucks are less likely to experience mechanical failures that could jeopardize the safety of drivers and other road users.

- Extended Vehicle Lifespan: Proper maintenance ensures that fleet trucks remain in good condition for a longer period, maximizing their lifespan and overall value.

- Improved Fuel Efficiency: Regular servicing and maintenance optimize engine performance, leading to better fuel economy and cost savings in the long run.

Cost Savings with a Preventive Maintenance Plan

Implementing a preventive maintenance plan can result in significant cost savings for fleet operations. By conducting routine inspections, servicing, and repairs, fleet managers can prevent major breakdowns that would otherwise lead to expensive repairs, downtime, and potential losses in revenue.

Additionally, proactive maintenance helps avoid emergency repairs, which are often more costly and disruptive to operations.

Components of a Preventive Maintenance Plan

Preventive maintenance plans for fleet trucks are crucial in ensuring the smooth operation of vehicles and minimizing unexpected breakdowns. Several key components should be included in a comprehensive maintenance plan to keep fleet trucks running efficiently.

Scheduled Inspections

Scheduled inspections play a vital role in a preventive maintenance plan for fleet trucks. Regular inspections help identify potential issues before they escalate into major problems, allowing for timely repairs and replacements. These inspections should cover all essential components of the vehicle, including engine, brakes, suspension, tires, and electrical systems.

Regular Fluid Checks and Replacements

Regular fluid checks and replacements are another essential component of a preventive maintenance plan for fleet trucks. Engine oil, transmission fluid, coolant, and brake fluid need to be regularly monitored and replaced according to the manufacturer's recommendations. Proper fluid levels and quality are crucial for the overall performance and longevity of the vehicle.

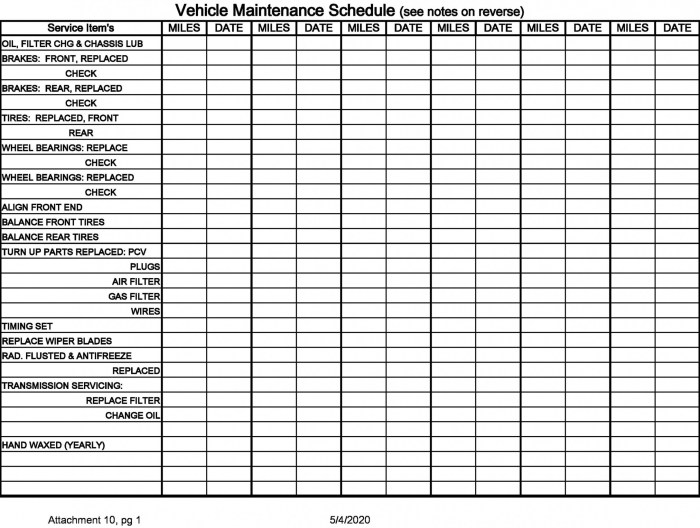

Component Replacement Schedule

Having a detailed component replacement schedule is key to maintaining fleet trucks in optimal condition. This schedule should include the replacement intervals for essential parts such as filters, belts, hoses, and spark plugs. Adhering to this schedule ensures that all components are in good working order and helps prevent unexpected breakdowns on the road.

Maintenance Record Keeping

Maintaining detailed records of all maintenance activities is essential for tracking the performance and condition of fleet trucks. These records should include dates of inspections, repairs, and replacements, as well as any issues identified during the maintenance process. Keeping accurate records helps in planning future maintenance tasks and ensures compliance with regulations.

Creating a Preventive Maintenance Schedule

Creating a detailed preventive maintenance schedule for fleet trucks is crucial to ensure the vehicles remain in optimal condition, minimizing downtime and costly repairs. Here are the steps to create an effective preventive maintenance schedule:

Determining Maintenance Frequency

- Consider the manufacturer's recommendations: Start by reviewing the manufacturer's guidelines for maintenance intervals based on mileage or operating hours.

- Assess the vehicle usage: Evaluate how frequently the fleet trucks are used and under what conditions to determine a suitable maintenance schedule.

- Factor in environmental conditions: Take into account the impact of environmental factors such as temperature, road conditions, and terrain on the maintenance requirements.

Prioritizing Maintenance Tasks

- Identify critical components: Determine which parts of the fleet trucks are most essential for safe operation and prioritize maintenance tasks accordingly.

- Refer to historical data: Review past maintenance records to identify recurring issues or components that require frequent attention.

- Utilize a risk-based approach: Assess the potential impact of component failure on vehicle performance and safety to prioritize maintenance tasks effectively.

Implementing a Preventive Maintenance Tracking System

Implementing a preventive maintenance tracking system is crucial for fleet trucks to ensure optimal performance, minimize downtime, and extend the lifespan of the vehicles.

Importance of Tracking Maintenance Activities

One of the key reasons for tracking maintenance activities is to have a comprehensive record of all maintenance tasks performed on each fleet truck. This information helps in identifying patterns, predicting potential issues, and scheduling future maintenance effectively.

- Preventive Maintenance Software: Utilizing specialized software can help streamline the tracking process by centralizing maintenance records, generating automated alerts for upcoming service intervals, and providing detailed reports for analysis.

- Telematics Systems: These systems use GPS technology to track the location, performance, and health of fleet trucks in real-time. Telematics systems can also monitor engine diagnostics, fuel consumption, and driver behavior to optimize maintenance schedules.

- RFID Technology: Radio-frequency identification (RFID) tags can be used to track maintenance activities by scanning them at various checkpoints. This technology offers a hands-free approach to recording maintenance data accurately.

Utilizing Technology for Streamlining Tracking Process

Technology plays a vital role in streamlining the preventive maintenance tracking process for fleet trucks. By leveraging advanced tools and systems, fleet managers can improve efficiency and accuracy in monitoring maintenance activities.

- Mobile Apps: Mobile applications provide a convenient way for technicians to log maintenance tasks, update service records, and receive notifications on the go. This real-time access to data ensures timely interventions and reduces the risk of overlooking critical maintenance tasks.

- Cloud-Based Platforms: Storing maintenance data on cloud-based platforms allows for easy accessibility, data sharing, and collaboration among team members. It also enables remote monitoring of fleet trucks and ensures that all stakeholders have up-to-date information at their fingertips.

- Predictive Analytics: Implementing predictive analytics tools can help in forecasting maintenance needs based on historical data, performance trends, and environmental factors. By proactively addressing potential issues, fleet managers can prevent costly breakdowns and maintain fleet reliability.

Ultimate Conclusion

Concluding our discussion on creating a Preventive Maintenance Plan for Fleet Trucks, remember that a well-thought-out plan can lead to enhanced efficiency, reduced downtime, and ultimately, cost savings.

FAQ Resource

What is the significance of regular maintenance for fleet trucks?

Regular maintenance ensures optimal performance, prolongs the lifespan of vehicles, and reduces the risk of unexpected breakdowns.

How often should preventive maintenance tasks be scheduled?

The frequency of maintenance tasks depends on factors like vehicle usage, manufacturer recommendations, and environmental conditions.

Why is it important to track maintenance activities for fleet trucks?

Tracking maintenance activities allows for better planning, timely interventions, and a comprehensive overview of the fleet's health.

![Costco Auto Insurance Review [2025]: Additional Discounts for Members ...](https://auto.infogarut.id/wp-content/uploads/2025/11/costco-car-insurance-reviews-120x86.jpg)

![13 Best Websites to Sell a Car for the Best Price [2025]](https://auto.infogarut.id/wp-content/uploads/2025/11/best-websites-to-sell-a-car-online-120x86.jpg)

![Costco Auto Insurance Review [2025]: Additional Discounts for Members ...](https://auto.infogarut.id/wp-content/uploads/2025/11/costco-car-insurance-reviews-350x250.jpg)